Also for pinch (driving) and brake rolls, a higher and constant friction value is required, particularly in case the strip surface is wet or oily. Conventional rolls have low friction values even when they are new, and generally deteriorate significantly after short time of operation. JVM Rolls are perfectly suitable for these different tasks, regardless of the strip surfaces being dry, wet or oiled. |

| Comparison or Friction Factors, Data of the Friction Values in µ |

| |

JVM

Roll |

Rubber Coated Roll |

| Steel strip |

Dry

Wet

Oily

|

0,52

0,44

0,36 |

0,36

-,-

0,01 |

| Stainless steel strip |

Dry

Wet

Oily |

0,29

0,27

0,25 |

-,-

-,-

-,- |

| Aluminium strip |

Dry

Wet

Oily |

0,29

0,31

0,32 |

0,36

-,-

0,01 |

| Copper strip |

Dry

Wet

Oily |

0,34

0,31

0,34 |

-,-

-,-

-,- |

| Brass strip |

Dry

Wet

Oily |

0,34

0,37

0,30 |

-,-

-,-

-,- |

|

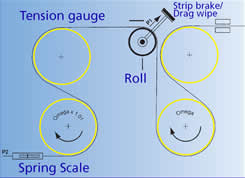

| Note: Coefficients of friction measured with a strip guide of 180° (see schematic drawing) |

|